Currently, the communication industry is increasingly reliant on high speed optical networks to support daily operations. It is a commonplace to see fiber optics being used in transmission lines and distribution lines, in generating stations, and even in substations. Since most of the fiber optic cables used in these situations are deployed in the outside-plant (OSP), more attention should be attached to the selection of the right optical cable. So, whether to choose ribbon optical cable or conventional loose tube cable in OSP deployment? Which one is more economically? This is what we will discuss today.

At the beginning, I’d like to give a brief introduction to ribbon and lose tube optical cable respectively.

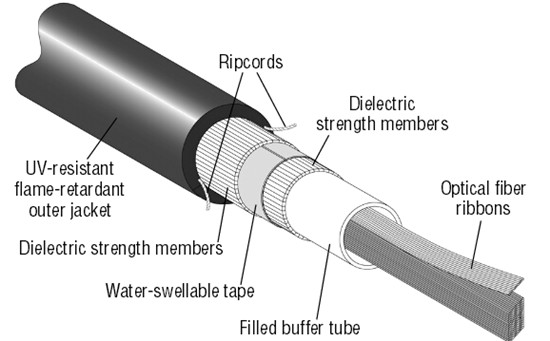

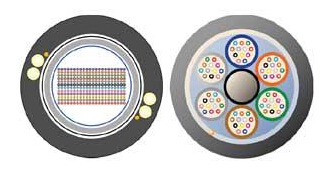

Ribbon optical cables provide an ideal choice for deployment in campus, building and data center backbone applications where fiber counts of more than 24 are required. Just like the stranded loose tube cable, ribbon cable offers robust performance as well. However, it is capable of accommodating the maximum fiber density relative to cable diameter. The cable design consists of 12 to 216 fibers organized inside a central tube and a non-flame-retardant jacket material is typically used in outside plant applications.

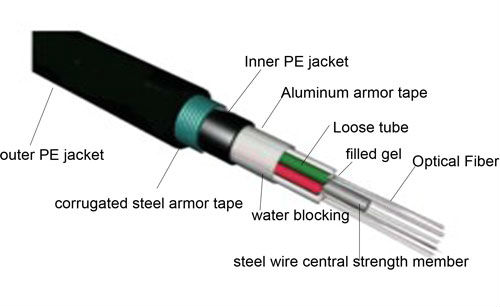

Loose tube optical cables are widely used for outside plant trunks because they offer exceptional and reliable protection for the fibers under high pulling tensions and can be easily protected from moisture with water-blocking gel or tapes. It typically consists of multiple buffer tubes that contain one to 12 fibers and are stranded around a central member. Contingent upon the deployment location, a non-flame or flame-retardant jacket is applied.

Both ribbon optical cables and loose tube optical cables are staples of the telecommunications industry. Both products perform well in harsh outdoor environments, and both are available in a multitude of configurations. However, the major differences between them lie in the manner in which the individual fibers themselves are packaged and managed within the cable. A ribbon optical cable has the individual fibers precisely bonded together, the number of which ranging from 4 to 24 fibers. Typically, they are bonded together in a group of 12 and placed inside a tube that holds multiple ribbons. In contrast, a loose tube optical cable design has between 2 to 24 individual fibers housed in multiple buffer tubes with each fiber detached from the other.

Apparently, both ribbon optical cable and loose tube optical cable obtain some merits and demerits concerning different deployment scenarios, this will be explained in the next part.

In some cases, it is better to adopt ribbon optical cable when the fiber counts hold a key issue. Since mass fusion splicing technology is enabled by ribbon optical cable, it can be spliced much more rapidly than loose tube cables. This advantage allows for less installation time, less installation labor cost, and significantly less emergency restoration time. Besides, It enables a smaller footprint in splice closures and telecommunications room fiber management. Ribbon optical cables offer greater packing density in higher fiber counts which enable more efficient use of limited duct space. And it is typically very cost competitive in counts above 96 fibers.

However, some applications such as fiber-to-the-home, require multiple cable access locations where we pull out only two to eight fibers from a cable for splicing using mid-sheath access techniques. In those instances, ribbon might be less practical for some carriers than conventional loose tube. There are still a few areas where either ribbon or loose-tube is the preferred option. For example, it takes four splices to repair a 48 fiber count ribbon cable compared to 48 splices for the loose-tube equivalent.

To conclude, there is not a single cable that fits all network designs perfectly and thoroughly. But it is essential to know the options and where they fit best, which may contribute to decrease installation time, labor cost, and emergency restoration time. Before choosing the optimum solution for the specific scenario, just remember to take cable costs, splicing costs and labor hours into consideration.