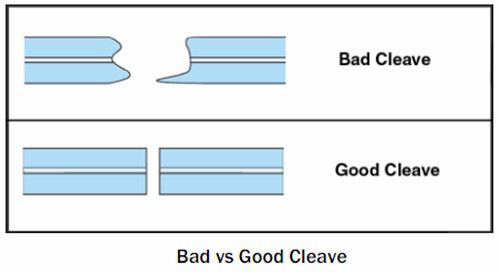

There is no doubt that cleaving the fiber properly is critical to achieve good fiber optic splices or terminations, especially when using the pre-polished connectors with internal splices. Imprecisely cleaving of the fiber ends, therefore, will result in improper matching. So, the end of the fiber must be cleaved to a 90 degree flat end when it is prepared for a connector or splice. However, technicians often encountered the problem that the end of the fiber strand is so small, making it is impossible to tell whether the strand has a flat end. To ensure smooth and precise fiber cleaving, a fiber optic cleaver is much needed. And in this article, we will offer you some useful information about fiber optic cleaver.

A cleave in an optical fiber is a deliberate, controlled break, which intends to create a perfectly flat end face, perpendicular to the longitudinal axis of the fiber. A fiber optic cleaver is a tool that holds the fiber under low tension, scores the surface at the proper location, then applies greater tension until the fiber breaks. Usually, after the fiber being scored, the technician will use a cleaver either bends or pulls the fiber end, stressing the fiber. And the fiber will break at the score mark under this stress, leaving a 90 degree flat end if all goes well. So the cleaver doesn’t cut the fiber but just breaks the fiber at a specific length.

We know that the closer to 90 degrees the cleave is, the greater chance you will have to match it with another cleaved fiber, then be spliced or mated by a connector. Thus, a proper tool with good technique is demanded for consistently achieving a 90 degree flat end. Good cleavers are automatic and can produce consistent results, irrespective of the operator. The user only needs to clamp the fiber into the cleaver and operate its controls. Some cleavers are less automated, making them more dependent on operator technique and therefore less predictable. There are basically two broad categories of fiber optic cleavers: scribe cleavers and precision cleavers.

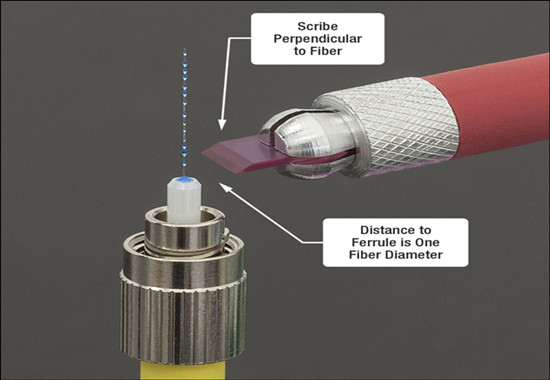

This type is based on a traditional cleaving method. It is typically used to remove excess fiber from the end of a connector before polishing, simply by using a hand tool called scribe. Scribe cleavers are usually shaped like ballpoint pens with diamond tipped wedges or come in the form of tile squares. The scribe has a hard, sharp tip, generally carbide or diamond, which is used to scratch the fiber manually. Then the operator pulls the fiber to break it. Since both the scribing and breaking process are under manual control, this method varies greatly in repeatability. Most field and lab technicians shy away from these cleavers as they are not accurate. However, if used in skilled hands, this scribe cleaver reduces the cost significantly for repairs, installation, and training classes.

Precision cleavers are the most commonly used cleavers in the industry. They use a diamond or tungsten wheel/blade to provide the nick in the fiber. Tension is then applied to the fiber to create the cleaved end face. The advantage of these cleavers is that they can produce repeatable results through thousands of cleaves by simply rotating the wheel/blade accordingly. Although more costly than scribe cleavers, precision cleavers can cut multiple fibers at one time with increased speed, efficiency, and accuracy. While in the past, scribe cleavers were widely used for fiber cleaving, precision cleavers are now developed to support various applications and multiple fiber cleaving. Precision cleavers contribute to better cleave, which ensures low splice loss and precision cleavers, besides, its blades have a much longer life span.

Then here comes the question: how to choose between scribe cleaver and precision cleaver? You can take this for reference: An experienced fiber optic technician achieves approximately 90% good cleaves with a scribe cleaver, while for precision cleaver, it produces 99% good cleaves. Since the difference is not big enough to help make a choice, I humbly suggest you to buy precision cleavers if you plan to use a lot of mechanical splices or pre-polished splice/connectors. And this will benefit you from the long run. If you decide to use inexpensive scribe cleavers, you’d better to learn how to use it properly. Follow directions, but also do what comes naturally to you when using the device, as they are sensitive to individual technique. Inspect the fibers you cleave to see how good they are and keep practicing until you can make consistently good cleaves.

Optical cleaver serves as an essential tool to get better fiber cleaving, which as well contribute to the fiber splice and termination. There are two types of fiber optic cleaver available: scribe cleaver and precision cleaver, and you can choose one based on your specific requirements and applications. But no matter what you choose, enough practicing is needed to get consistently good cleavers.