As the cleanliness of the interfaces in fiber optic networks can directly affect the transmission quality, fiber optic cleaning is a must-have process during fiber optic network installation, testing, and maintenance. You should always keep it in mind. You need to clean the fiber optic interface on the test equipment and fiber optic connectors before you do the test. You need to clean the fiber optic connector or interfaces regularly in your daily maintenance. Various fiber optic cleaning methods are created. No matter you use dry cleaning or wet cleaning, basic tools are needed. However, we might be confused during the selection of the fiber optic cleaning tools, because there are so many different kinds of fiber optic connectors, interfaces, and working environments. This post is to introduce the most commonly used fiber optic cleaner for different kinds of fiber optic connectors.

One-Push Fiber Optic Cleaner

One-push fiber optic cleaner is one of the most popular fiber optic cleaners which eliminates the use of alcohol or solvents. Thus, it can save time efficiently with excellent performance. I would like to call it “Click and Cleaned”. Here I will introduce how to use one push fiber optic cleaner first.

The following picture is the top of a one-push connector, the cleaning tip of the cleaner is covered with a guide cap for fiber optic connectors. A cover is on the top of the guide cap, which can protect the cleaning tip combined with the guide cap.

If you need to clean a fiber optic connector, the guide cap plays the function of a fiber optic adapter. Insert the cleaning tip into the connector with the guide cap as shown in the following picture, and press the cleaner until you hear a push. Then a cleaning is done by fiber optic cleaner.

If you need to clean a fiber optic adapter, you should first remove the whole guide cap on the one-push cleaner. Then insert the cleaning tip into the adapter as shown in the following picture. Just by simple pressing, until you hear the click, a cleaning for a fiber optic adapter is done. It is very useful during tests, cause the test equipment usually has an interface of the adapter.

Different types of connectors might have ferrules of different sizes. Thus, there are also accordance fiber optic cleaners for various connectors. Introduces several popular one-push fiber optic cleaners for different connectors.

One-Push Cleaner for LC/MU 1.25mm Ferrules

- Price: $35.00

- Item Part Number: ATC-NE-E1

- Package Form: LC cleaner

- Target Use: LC, MU

- Cleaning Times: Over 750 times per unit

One-Push Cleaner for SC/ST/FC 2.5mm Ferrules

- Price: $35.00

- Item Part Number: ATC-NE-E3

- Package Form: SC cleaner

- Target Use: SC, ST, FC, LSH

- Cleaning Times: Over 750 times per unit

One-Push Cleaner for MTP/MPO Connector

- Price: $45.00

- Item Part Number: ATC-NE-M1

- Package Form: One-push cleaner

- Target Use: MPO/MTP

- Cleaning Times: Over 600 times per unit

Reel-Type Fiber Optic Cleaner

Reel-type fiber optic cleaner contains a refillable lint-free reel of cloth that is moved after each cleaning, always presenting a clean surface. Reel-type fiber optic cleaners come in different package forms, but most of them are in cassette form.

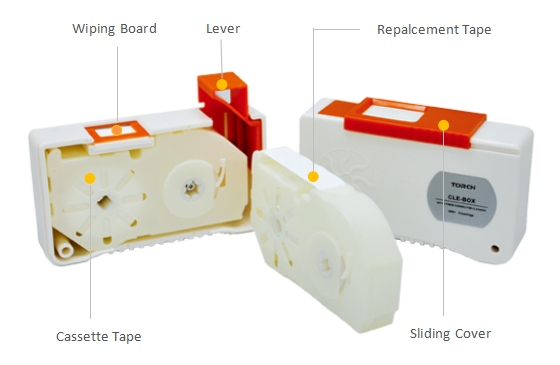

This type of fiber optic cleaner can clean a wide range of fiber optic connectors, which also avoids the use of alcohol or solvents. The following shows the basic structure of a reel-type fiber optic cleaner and its replacement tape. The cleaning with this cleaner is also very simple. Firstly depress a lever to expose the cleaning slot and cloth. Second, slide the connector end face gently. Third, keep the connector perpendicular to the cleaning surface. Then a cleaning is done.

CLE-BOX Fiber Optic Cassette Cleaner for LC/MU/SC/FC/ST/MPO/MTRJ

- Price: $19.00

- Item Part Number: FOCC-301

- Package Form: Cassette cleaner

- Target Use: LC, SC, FC, ST, MU, D4, DIN

- Cleaning Times: Over 500 times per unit

Attention: The products mentioned in this article may have unstable availability due to timeliness. For more information, please visit www.fs.com and consult our online customer service.

The above-mentioned fiber optic cleaners are just a small part of the cleaning product family and are generally for dry cleaning. Kindly visit FS.com or contact sales@fs.com for more details about wet cleaning for other fiber optic cleaning products.