Cabling component selection actually serves as the very primary stage of installing the system, and it can pose continuous impact on the reliability and flexibility of the whole network. It is sometimes overwhelming for installers to narrow down and select the right combination of cabling components since there are quite amount of them available on the market. Deploying the right equipment can avoid future cabling issues. So, before making the decision, you’ d better consider compatibility, ease of installation, cost, density, durability, aesthetics, accessibility, flexibility, and delivery times. Here, we offer you some advice on how to choose the right cabling component.

Patch cables are used to connect end devices to patch panel ports, and to connect ports between two patch panels. A big problem concerning patch cables is the design and quality of the terminations, especially for RJ45 copper terminations. The quality of patch cables matters a lot since they will experience the most wear and tear. Hence when purchasing patch cable, please take the following aspects into account:

- Specification of the cable, avoid cheap, low-quality cables

- Compliance to EIA/TIA/IEEE standards

- Thickness of the copper cable, the thicker the better

- Flexibility of the cable, the less cable memory the better

- Connector design and quality

- Availability of colors and categories, prepared for current and future needs

- Support for future applications

Patch panel enables easy management of patch cables and links the cabling distribution areas. Multimedia patch panels are ideal since they allow several different cable connectors to be used in the same patch panel. As for the types of connectors, consider LC for fiber and RJ-45 for copper. While mixing cable types within the same patch panel is not best practice, it is more flexible for housing ad-hoc cable types. The best solution is to separate the fiber cabling from the copper cabling in separate patch panels. Patch panels also come in modular styles, for example, for an MPO structured system, which features faster installation and lower labor cost. And there are angled patch panels for high-density areas cabling. Consider the following when selecting patch panels.

- Spacing between ports aids insertion and removal of cables

- Sturdy connectors: some panels have loose connectors and tend to fall out during cable installation and removal

- Orientation of ports in the panel

- One-piece dust covers for ports (recommended for high traffic areas)

- Density supported (24 ports or 48 ports per 1U panel)

- Compatibility with industry standard connectors and racks, and space for labeling on the front of the panel

- Added cable support for the intended cable types on the back of the panel, this is critical and overlooked by many manufacturers.

Choose the fire-rated plenum type. There are no high-density copper solutions, but you can choose a modular cabling system. As for fiber, high density involving 24-strand to 96-strand cables in adequate. MPO trunk cables (up to 72 fiber strands can be housed in one MPO connection) can be installed if you are using MPO style cabling. It is necessary to evaluate the cost of materials and labor for terminating connections into patch panels. These cables will most likely end up under raised floors, or over the ceiling, or in overhead cable pathways.

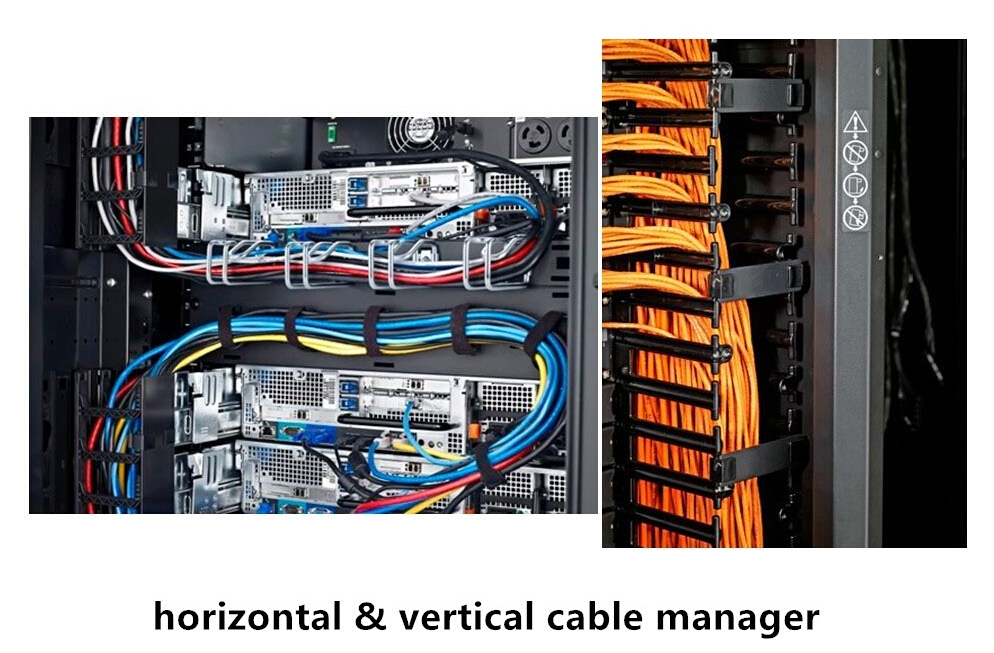

There are horizontal and vertical cable managers for different cabling methods. Horizontal cable managers contribute to proper and neat routing of the patch cables from equipment in racks and protect cables from damage. It is vital to reach a balance between cable manager height and cable density supported. 1U and 2U horizontal cable managers are the most common ones, with metal and flexible plastic available. The ideal cable manager has a big enough lip for positioning and removing cables easily, and has sufficient depth to accommodate the quantity of cables planned for the area. Remember that 30% space in the cable managers should be left for future growth.

As for vertical cable managers, additional space is required to manage the slack from patch cords. And you should ensure that the managers can easily route the largest cable diameter in your plan. Allow for 50% growth of cables when planning the width and depth of the vertical cable manager. For dynamic environments, d-rings type cable managers are used to manage cables on the back side of the racks. Whereas for static environments, consider installing another vertical cable manager behind the rack, which allows for access to components in the space between the racks.

Known as overhead cable trays as well, they allow placement of additional cables for interconnecting devices between racks on an ad-hoc basis. Check support for cable bend radius, weight allowance, sagging points for cables, and flexibility in installing the pathways. Besides, ensure that pathways allow cable drop points where needed.

Cable ties are used to hold a group of cables together or to fasten cables to other components. Since there is a tendency for users to over-tight zip ties, which definitely can impact performance, it is advised to choose velcro cable ties versus zip ties. Velcro cable ties are available in a roll or in pre-determined lengths. Using cable ties to bundle groups of relevant cables together will help you better identify cables and facilitate overall cable management.

It is clear that selecting the right cabling components to best satisfy your specific cabling structure can be time and energy consuming, with the components range from patch cables to ports to panels and to cable managers. The article simply provides you a reference guideline to compare and select. And we hope it could release you from the laborious and demanding selection task.