Fiber optic splicing is an important method of joining two fiber optic cables together. It is a preferred solution when an available fiber cable is not sufficiently long for the required run. Besides, fiber optic splicing is designed to restore fiber optic cables. In case they are accidentally broken. Nowadays, fiber optic splicing is widely deployed in telecommunications, LAN (Local Area Network) and networking projects. Typically, we can undertaken fiber optic splices two ways: fusion splices and mechanical splices. This paper firstly illustrates the specific process of fusion splicing method and mechanical splicing method. And then makes a comparison of the two methods for your reference.

Fiber Optic Splicing: Fusion Splicing Method

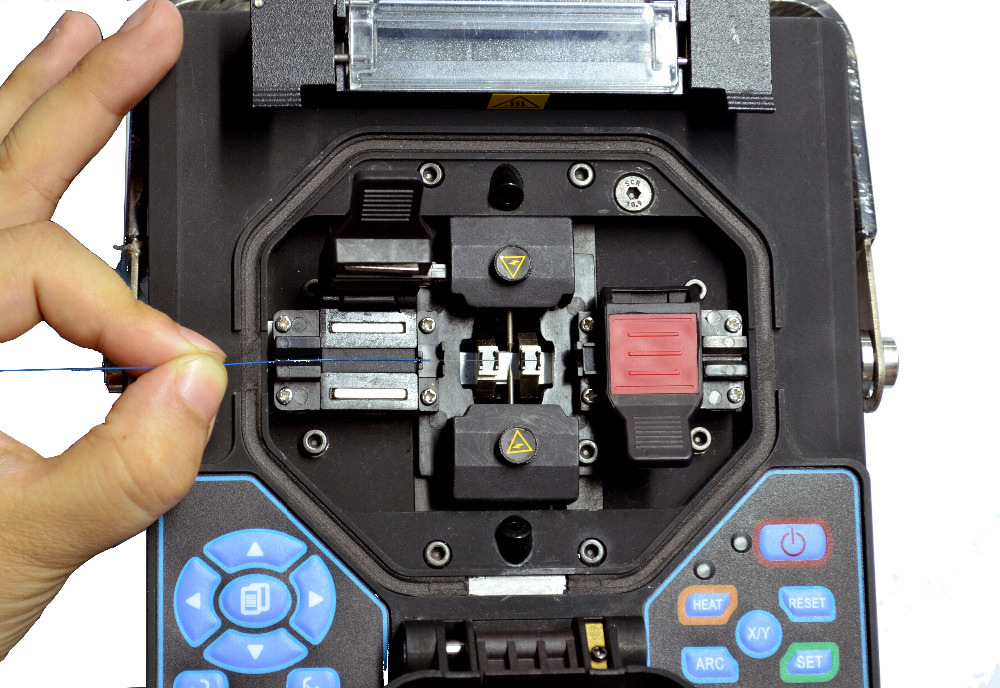

Fusion splicing is a permanent connection of two or more optical fibers. The two fibers are welded together with an electronic arc. This is the most widely used method of fiber optic splicing. Because it provides the lowest loss, less reflectance, strongest and most reliable joint between two fibers. When you adopt this method, fusion splicing machines are often used. Generally, there are four basic steps in the fusion splicing process. They are illustrated in following one by one.

The splicing process begins with the preparation for both fibers ends to be fused. So you need to strip all protective coating, jackets, tubes, strength members and so on. And you just leave the bare fiber showing. It is noted that the cables should be clean.

A good fiber cleaver is crucial to a successful fusion splice. The cleaver merely nicks the fiber and then pulls or flexes it. So to cause a clean break rather than cut the fiber. The cleave end-face should be perfectly flat and perpendicular to the axis for a proper splice.

When you fuse the fiber, there are two important steps: aligning and melting. Firstly, you need to align the ends of the fiber within the fiber optic splicer. After proper alignment, you need to utilize an electrical arc to melt the fibers. So you can permanently weld the two fiber ends together.

A typical fusion splice has a tensile strength between 0.5 and 1.5 lbs. And it is not easy to break during normal handling. However, it still requires protection from excessive bending and pulling forces. By using heat shrink tubing, silicone gel and mechanical crimp protectors can keep the splice from outside elements and breakage.

Fiber Optic Splicing: Mechanical Splicing Method

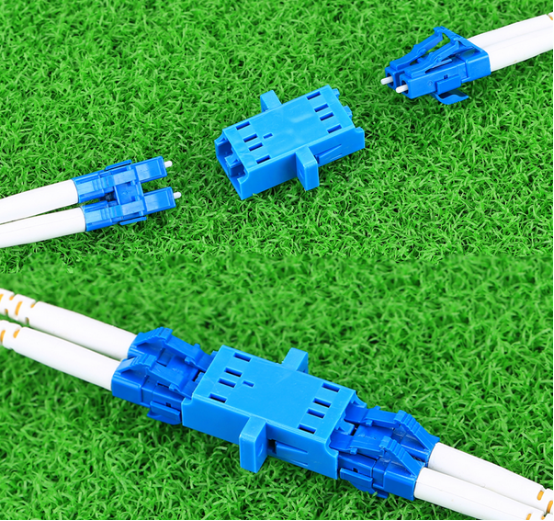

If you want to make splices quickly and easily, the mechanical splice is a better choice. A mechanical splice is a junction of two or more optical fibers. The fibers are aligned and held in place by a self-contained assembly. A typical example of this method is the use of connectors to link fibers. This method is most popular for fast, temporary restoration and splicing multimode fibers. The fibers are in a premises installation. Like fusion splice, there are also four basic steps in a mechanical splice.

Fiber preparation is practically the same as that of fusion splicing. Just remove the protective coatings, jackets, tubes, and strength members. So we can see the bare fiber. Then ensure the cleanliness of the fiber.

The process is the same as the cleaving of fusion splicing. It is necessary to obtain a cut on the fiber exactly at right angles to the axis.

In this step, we don’t use heating as infusion splice. We simply connect the fiber ends together inside the mechanical splice unit. The index matching gel inside the mechanical splice apparatus is helpful. Because it can couple the light from one fiber end to another.

Once fibers are spliced, we place them in a splice tray and then in a splice closure. Outside plant closures don’t need to use heat. We carefully seal shrink tubing to prevent moisture damage from the splices.

Which Method is Better?

Both fusion splicing and mechanical splicing method have their advantages and disadvantages. We need to Choose fusion splice or mechanical splice depends on the applications.

The fusion splicing provides a lower level of loss and a higher degree of permanence than mechanical splicing. However, this method needs to use expensive fusion splicing equipment. In view of this, we tend to use fusion splice for the long and high data rate lines. These rate lines are unlikely to be changed once installed.

The mechanical splicing is often used in these situations. When splices need to be made very quickly and the expensive equipment for fusion splices are not available. Some mechanical fiber optic splice allows both connection and disconnection. So a mechanical splice can be used in not permanent situations.

Conclusion

Fiber optic splicing is an important method in the installation of fiber optic networks. We need to Choose fusion splice or mechanical splice depends on the applications. When you do fiber splicing, you need to follow the specific instructions strictly for perfect splices. Besides, keeping all splicing tools clean is also important.

Related Article: Tips for Fiber Splicing and Termination

Related Article: Fusion Splicer: A Good Helper for Optical Fiber Splicing